Automotive-Grade Components in Space: Why Car Parts Are Going to Orbit

How automotive industry standards are enabling affordable, reliable nanosatellites

For decades, satellite electronics were defined by extreme specialization. Space-grade components were engineered in small quantities, tested at extraordinary cost, and designed to function for decades in harsh environments. These parts were reliable, but they were expensive, slow to obtain, and limited to organizations with large budgets and long timelines.

A transformation is now underway. Automotive-grade components, once unthinkable for space missions, are going to orbit. Combined with smart engineering techniques and shorter mission lifetimes, they are changing the economics and accessibility of space.

Automotive Standards Meet Space Requirements

Automotive systems operate every day in environments that are more extreme than many assume. Under the hood of a car, components must withstand high vibration, temperature swings from below freezing to over 120C, radiation from the sun, and continuous operation for many years without repair.

These demands align surprisingly well with many modern satellite missions, especially for spacecraft designed for operational lifetimes of two to three years. That mission profile describes most emerging Low Earth Orbit (LEO) constellations and nearly all nanosatellite deployments.

As Guido Parissenti, CEO of Apogeo Space, noted, Automotive components have a strong baseline reliability. When properly protected through shielding and redundancy, they deliver excellent results in orbit at substantially lower cost. The success of companies like Apogeo Space illustrates that this approach works and scales.

A Clear Market Shift to LEO and COTS

Legacy satellites in Geostationary Orbit (GEO) can weigh several tons, cost hundreds of millions of dollars, and require three to five years to design and build. Their 25 to 30 year lifespan demands the highest reliability and most expensive parts.

By contrast, the growth engine of today's space economy is in LEO. Satellites in LEO typically weigh between 1 and 1,000 kilograms and orbit much closer to Earth. They can be produced in months instead of years, at a fraction of the cost. A large percentage use commercial off-the-shelf (COTS) components adapted for space environments. These attributes make LEO ideal for high-bandwidth connectivity, Earth observation, IoT networks, and space-to-space data infrastructure.

The momentum is clear. Analysts project sustained double digit annual growth of the nanosatellite and microsatellite market as demand for LEO constellations accelerates. Faster innovation cycles require faster manufacturing cycles, and automotive-grade components support that model.

Engineering Protections Enable Space Performance

Automotive-grade components are not placed into orbit without modification. Engineers employ a layered protection strategy to ensure mission reliability:

- Selective shielding reduces exposure to radiation and thermal variance

- Software monitoring identifies and corrects non-destructive radiation effects

- Redundant circuits ensure the system continues functioning even if a component experiences an upset

- Electrical safeguards limit the risk of radiation-induced latch-up and power faults

- Smart architectural design limits single points of failure

This approach does not claim to eliminate risk. Instead, it balances performance with cost, allowing spacecraft to operate reliably for the duration of their intended mission without carrying the financial burden of decades of survivability.

A NASA NEPP briefing compared automotive AEC-Q standards against MIL-PRF space standards and concluded that automotive parts provide significant quality and environmental stress screening. Additional protections can close the gap for short- and medium-duration missions. Source: NASA NEPP Workshop, Sung Hong, 2018

Rethinking Mission Lifecycles

Traditional satellites were optimized for endurance: 10 to 15 year missions for LEO and 25 to 30 years for GEO. That requirement dictated space-grade components.

But the value proposition has changed. Technology evolves too quickly for long-life satellites to remain competitive. If a constellation can refresh every two to three years, operators can continuously deploy:

- New computing architectures

- More efficient solar cells and batteries

- Improved sensors and communications payloads

- Better autonomy and edge processing

This eliminates the need to support outdated technology for a decade or longer. It also reduces mission risk by minimizing exposure to component aging and obsolescence.

American Manufacturing Strength

Automotive-grade components open the door to a strong domestic supply chain advantage. The United States leads globally in automotive electronics and advanced manufacturing. Those suppliers are audited, reliable, and optimized for scale. For U.S. spacecraft developers, sourcing automotive-grade components domestically has clear benefits:

- Reduced foreign dependency

- Faster procurement and lead times

- Stronger export compliance positioning

- Support for American manufacturing jobs

This aligns directly with strengthening the U.S. industrial base for space systems.

Significant Cost Reduction

Traditional space-grade components are produced in low volumes with specialized testing. That drives prices into the tens or hundreds of thousands of dollars for a single avionics module.

Automotive-grade components benefit from high-volume economies of scale. When appropriately integrated into satellite systems, costs can be 50 to 80 percent lower than those of traditional small satellite systems. That cost advantage enables:

- Affordable constellation deployment at scale

- Larger fleets for global services

- Prototyping missions and technology demonstration

- University and nonprofit access to orbit

This shift turns space from a one-shot opportunity into an iterative development environment.

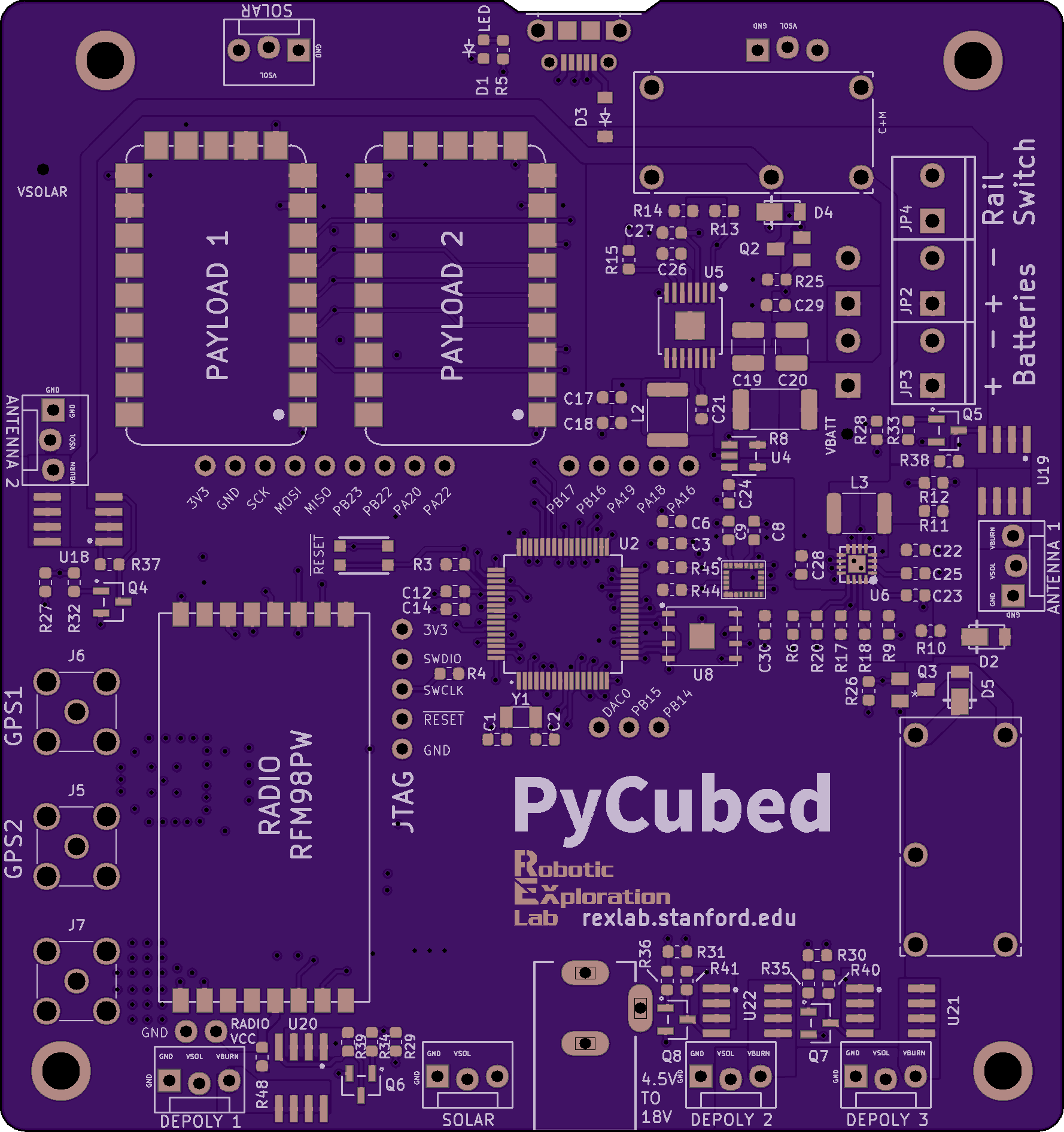

Blackwing Space: Automotive-Grade by Design

Blackwing Space was founded on this philosophy. Our nanosatellite platforms are based on commercial and automotive-grade components, delivered in an architecture designed for mass manufacturing, rapid integration, and short mission cycles.

This product-driven approach ensures:

- Lower economic barriers to launch for commercial and research missions

- A modular building block design compatible with open standards

- Fast customer integration timelines using accessible technology

- Consistent reliability through shielding, redundancy, and autonomous fault handling

- Support for U.S. supply chains and industrial capabilities

We also support optional upgrades. Customers requiring enhanced radiation tolerance or extended mission life can select space-grade component alternatives and hardened configurations, balancing mission needs with budget considerations.

Our inaugural mission, Baby Bird, scheduled for launch in 2026, establishes the flight heritage that underpins this scalable and affordable Space 3.0 approach.

Our commitment: capability that improves every launch cycle, not every decade.

Proven in Orbit

The industry has already validated that automotive-grade components work in space. NASA has flown COTS and automotive-derived hardware for over two decades. Every JPL mission since the Mars Exploration Rovers has included COTS electronic components.

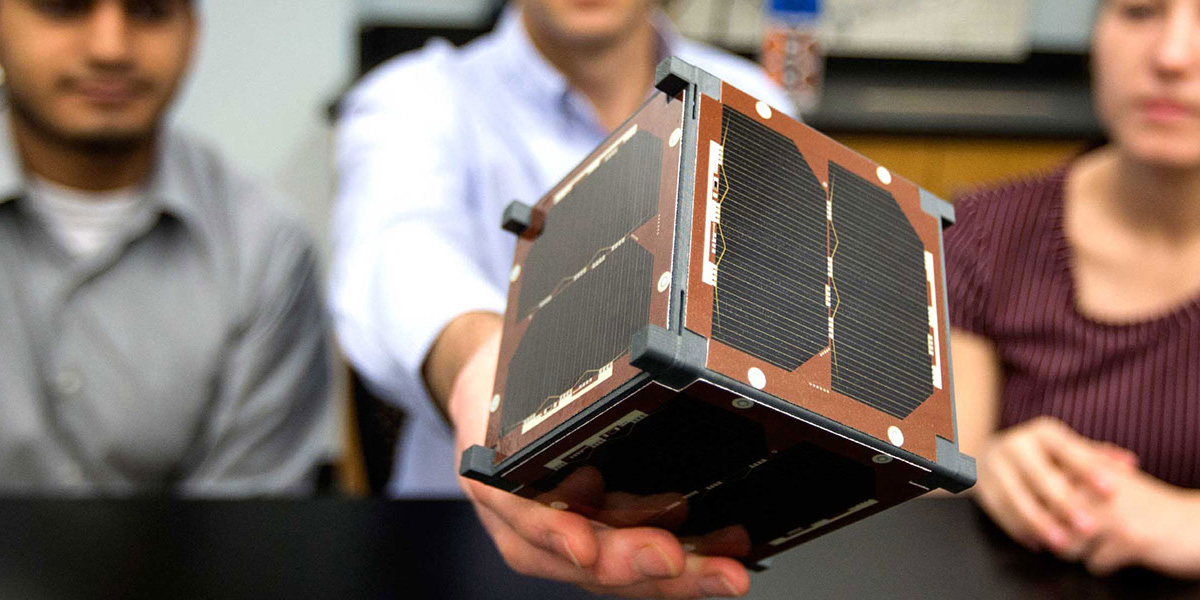

Commercial operators such as Apogeo Space and multiple CubeSat constellations have demonstrated reliable performance using this approach in LEO environments.

A New Reality for Space Access

Not every mission requires exotic, deep space-grade technology. As the space industry continues to evolve toward rapid, affordable deployment, automotive-grade components are enabling innovation that was previously cost-prohibitive.

The message is clear: space does not need to be expensive to work. By adapting the same components that power innovation on Earth, the industry can accelerate progress in orbit.

Blackwing Space is proud to be part of this transformation. The future belongs to space systems that can be built faster, launched sooner, iterated continuously, and scaled globally. Automotive-grade technology is a key enabler of that future.