Space 3.0 and the Rise of Rapid-Response Satellites

Why the future of satellites is defined by speed, adaptability, and rapid deployment

The next era of space innovation is not being built in the clean rooms of legacy aerospace giants. It is being built in commercial facilities where satellites are manufactured like hardware products, deployed in months instead of years, and refreshed before their technology becomes obsolete. This is Space 3.0, and speed is its defining characteristic.

Consider what speed actually means in this context. A traditional satellite program operates on a 24 to 36-month timeline from contract signature to launch. By the time the spacecraft reaches orbit, the processor inside is already two generations behind what you can buy commercially. The radio architecture reflects the spectrum regulations in place when the project started, not what is available today. The mission requirements for which the satellite was built may have evolved or disappeared entirely.

This model worked when space was an exclusive domain and satellites were expected to operate unchanged for 10 to 15 years. It breaks down completely when space becomes operational infrastructure that must respond to evolving threats, changing markets, and emerging technologies in real time.

Why the Urgency Emerged Now

Space has transitioned from a strategic capability to a critical infrastructure layer supporting communications, navigation, Earth observation, defense operations, and commercial services that touch every sector of the economy. This transition created a fundamental mismatch between how quickly mission needs evolve and how quickly traditional space systems can respond.

When a wildfire breaks out, disaster coordinators need persistent overhead imaging within hours, not a mission study that delivers capability eighteen months later. When maritime shipping patterns shift or geopolitical tensions escalate, operators need to redirect sensing assets or deploy new nodes immediately. When global IoT networks discover coverage gaps or new customer demand in underserved regions, they need orbital capacity that can launch within a quarter, not a multi-year procurement cycle.

The U.S. Space Force has recognized this reality by making responsive space and tactically relevant launch timelines a core strategic priority. Commercial operators face the same pressure from a different direction: competitive advantage now belongs to whoever can iterate fastest, test new services in orbit, and respond to customer needs before the opportunity window closes.

The Architecture Shift: From GEO Monuments to LEO Refresh Cycles

Traditional geostationary satellites represent a monument-building approach to space. Each spacecraft is engineered as a singular, high-value asset designed to operate unchanged for 10 to 15 years at 36,000 kilometers altitude. The engineering philosophy prioritizes longevity over adaptability, which drives up cost, extends development timelines, and locks operators into whatever technology stack existed when the design was frozen years before launch.

Space 3.0 inverts this model entirely. Low Earth Orbit constellations built around 2 to 3 year refresh cycles embrace technology obsolescence instead of fighting it. Operators deploy current-generation hardware, extract value during its economically optimal lifespan, then replace it with the next generation carrying better processors, more capable sensors, and upgraded communications systems.

This approach reduces technical risk by shortening the window between design decisions and operational validation. It eliminates the catastrophic consequences of single-point failures, because constellation architecture assumes individual satellites are replaceable assets rather than irreplaceable monuments. Most importantly, it aligns space operations with the pace of commercial technology development, ensuring that orbital assets remain competitive with terrestrial alternatives.

Manufacturing Philosophy: Satellites as Productized Platforms

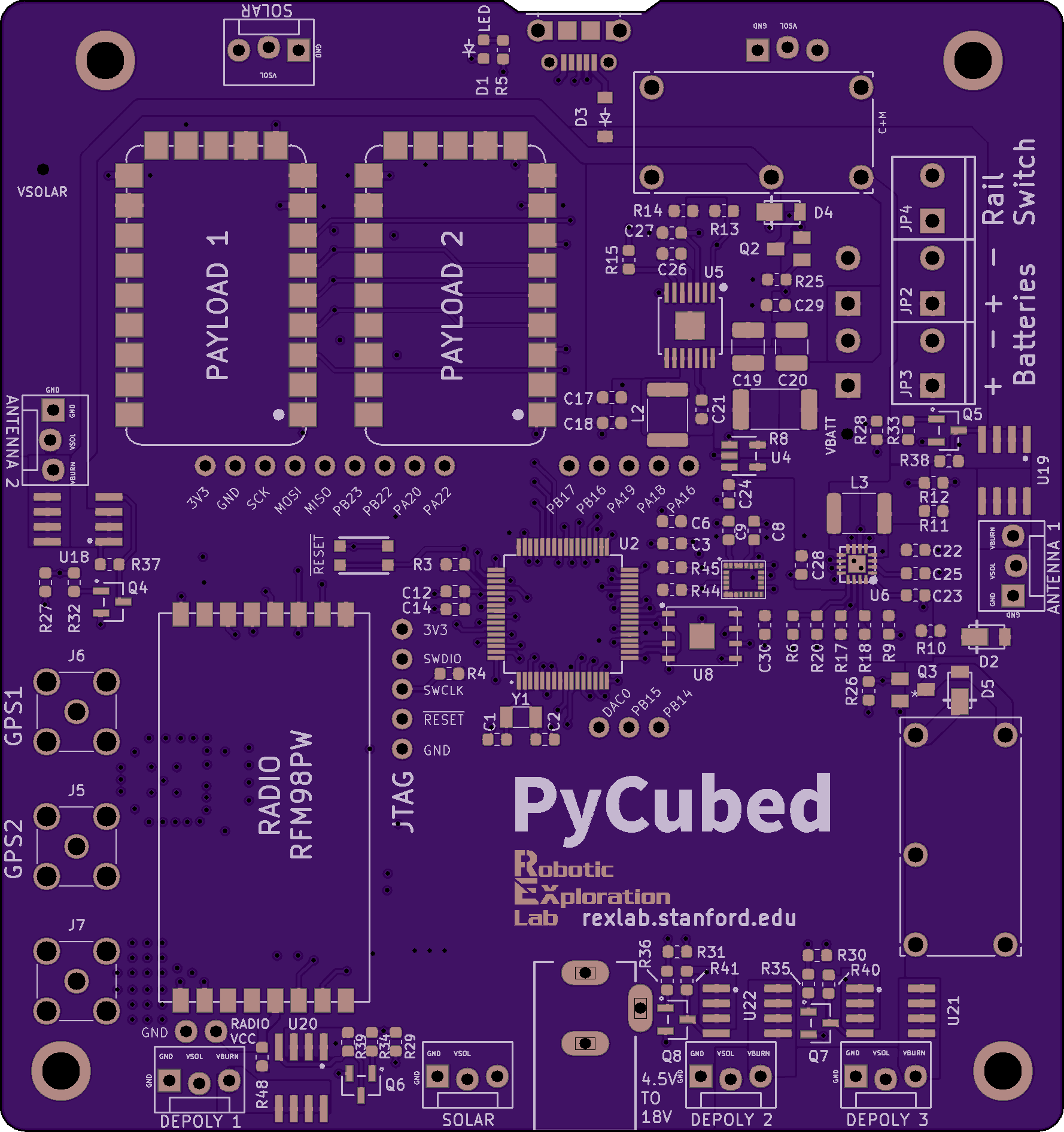

The shift to rapid deployment timelines requires a corresponding shift in how satellites are manufactured. Space 3.0 introduces product-line thinking to spacecraft development, where standardized platforms support mission-specific payloads through repeatable manufacturing processes and common interfaces.

Standardization happens at multiple levels. Electrical interfaces follow documented standards so payload developers can integrate without custom avionics for each mission. Mechanical interfaces use common mounting patterns and thermal management approaches. Software architectures provide open APIs and modular flight software that can be reconfigured rather than rewritten for each customer.

This transforms spacecraft from bespoke engineering projects into productized platforms that share manufacturing processes, supply chain relationships, and validation procedures across multiple missions. The result is a dramatic reduction in non-recurring engineering, faster delivery schedules, and lower per-unit costs that enable entirely new mission classes and business models.

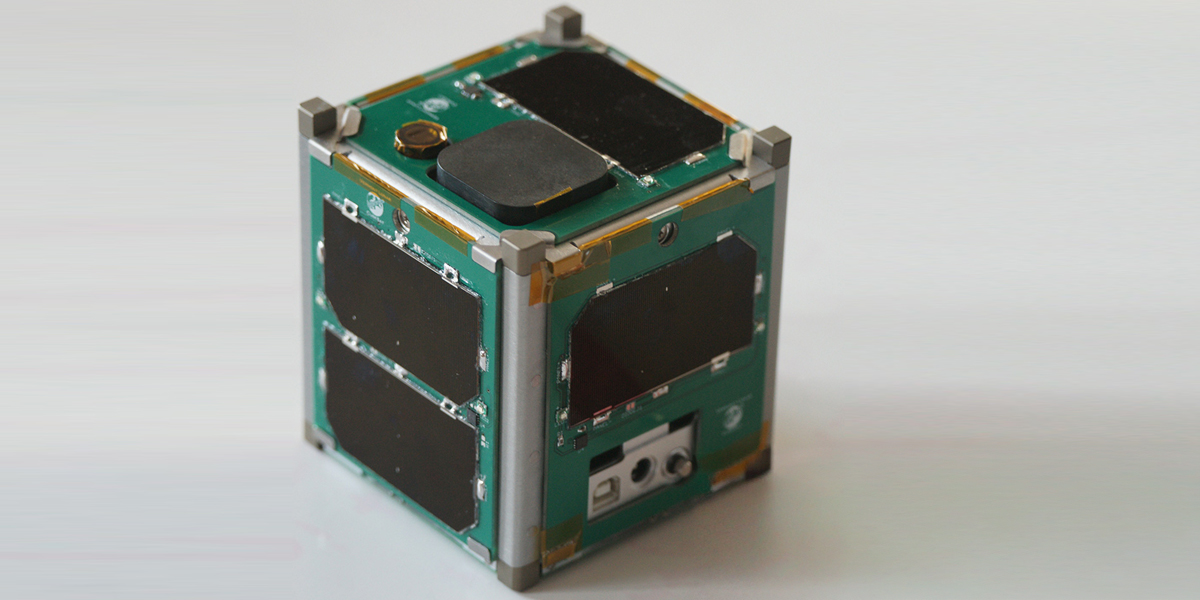

Blackwing Space: Built for Rapid Delivery

Blackwing Space is developing commercial nanosatellite platforms in Nashville, Tennessee, purpose-built for rapid deployment timelines. Our Sparrow (3U), Kestrel (6U), and Osprey (12U) platforms deliver concept-to-orbit capability in 3 to 8 months depending on payload complexity and mission requirements.

Our approach prioritizes American manufacturing with domestic component sourcing wherever mission requirements allow. We leverage automotive-grade electronics and proven manufacturing processes from other high-reliability industries to accelerate delivery without compromising performance. Standardized payload interfaces mean research institutions, commercial operators, and defense customers can integrate their missions without waiting for custom bus development.

As Tennessee's first dedicated nanosatellite manufacturer, Blackwing strengthens U.S. industrial capacity in a strategically critical sector while enabling customers to operate at commercial speed. We provide optional mission operations support and regulatory assistance for organizations that need turnkey deployment capability from contract signature through on-orbit operations.

The Competitive Advantage of Speed

Organizations that adopt rapid-refresh space architectures gain strategic flexibility that fundamentally changes what becomes possible. They can test new services in orbit, validate market assumptions with real operational data, and iterate their technology stack in response to actual customer feedback rather than pre-launch predictions.

When a competitor takes eighteen months to deploy a new capability, rapid-response operators can launch, learn, adjust, and relaunch before the competitor reaches orbit. When technology advances or mission priorities shift, they can incorporate changes immediately rather than absorbing the sunk cost of outdated hardware. When constellation expansion becomes necessary to serve new markets or coverage areas, they can scale capacity within quarters instead of waiting years for procurement cycles to complete.

This operational tempo represents a categorical advantage, not an incremental one. It transforms space from a domain where first-mover advantage is permanent into one where continuous iteration wins.

Redefining What Space Access Means

Space 3.0 expands who can operate in orbit and how orbital assets are used. When satellites can be purchased like enterprise hardware, launched on commercial timelines, and upgraded regularly through constellation refresh, mission classes that were previously uneconomical become viable. Universities can deploy research constellations. Commercial operators can test new services with manageable capital risk. Defense organizations can field tactical capabilities that match the urgency of operational requirements on the ground.

Rapid-response satellites are not just faster versions of traditional spacecraft. They represent a fundamentally different approach to how orbit is accessed and used—one that prioritizes adaptability over longevity, iteration over perfection, and deployment speed over design optimization.

Blackwing Space builds American-made nanosatellites engineered for this new operational reality. Contact us to discuss your mission requirements and explore what becomes possible when space capabilities move at commercial speed.