AI-Designed Satellites: The Race to Automate Nanosatellite Development

Proteus Space just launched the world's first AI-designed satellite in 9 months. It won't be the last. Here's why artificial intelligence is about to transform how every nanosatellite company designs, builds, and operates spacecraft.

On November 28, 2025, Proteus Space made headlines by launching MERCURY ONE - the world's first AI-designed satellite. More impressive than the "first ever" title was the timeline: they went from blank page to launch-qualified ESPA-class spacecraft in just 9 months.

That's not an incremental improvement. That's a complete paradigm shift.

Their MERCURY platform used artificial intelligence to evaluate vendors autonomously, select components based on flight heritage and technical fit, and generate a payload-tailored satellite design at machine speed. The result? A four-payload spacecraft delivered faster than most traditional programs complete their preliminary design review.

This Is Just The Beginning

While Proteus deserves recognition for being first to orbit with an AI-designed spacecraft, the real story isn't about one company or one mission. It's about what comes next.

AI-assisted satellite design isn't a novelty - it's becoming table stakes. The economics are too compelling, the timelines too compressed, and the technical advantages too significant for the industry to ignore. Within 24 months, virtually every competitive nanosatellite manufacturer will be integrating artificial intelligence into their design, manufacturing, and operations workflows.

The question isn't whether AI will transform nanosatellite development. It's how fast, and who will do it best.

Why AI Makes Sense for Nanosatellites

The nanosatellite market is uniquely positioned to benefit from AI integration:

- Design Complexity at Small Scale: CubeSats pack immense functionality into shoebox-sized packages. Every cubic centimeter matters. AI excels at multi-objective optimization problems, finding the perfect balance between mass, power, thermal performance, and structural integrity across thousands of design permutations.

- Rapid Iteration Demands: Traditional satellite design cycles measured in years don't work when your orbital lifespan is 2-3 years. Nanosatellite manufacturers need to iterate faster. AI compresses design cycles from months to weeks, letting teams test more configurations and reach optimal solutions faster.

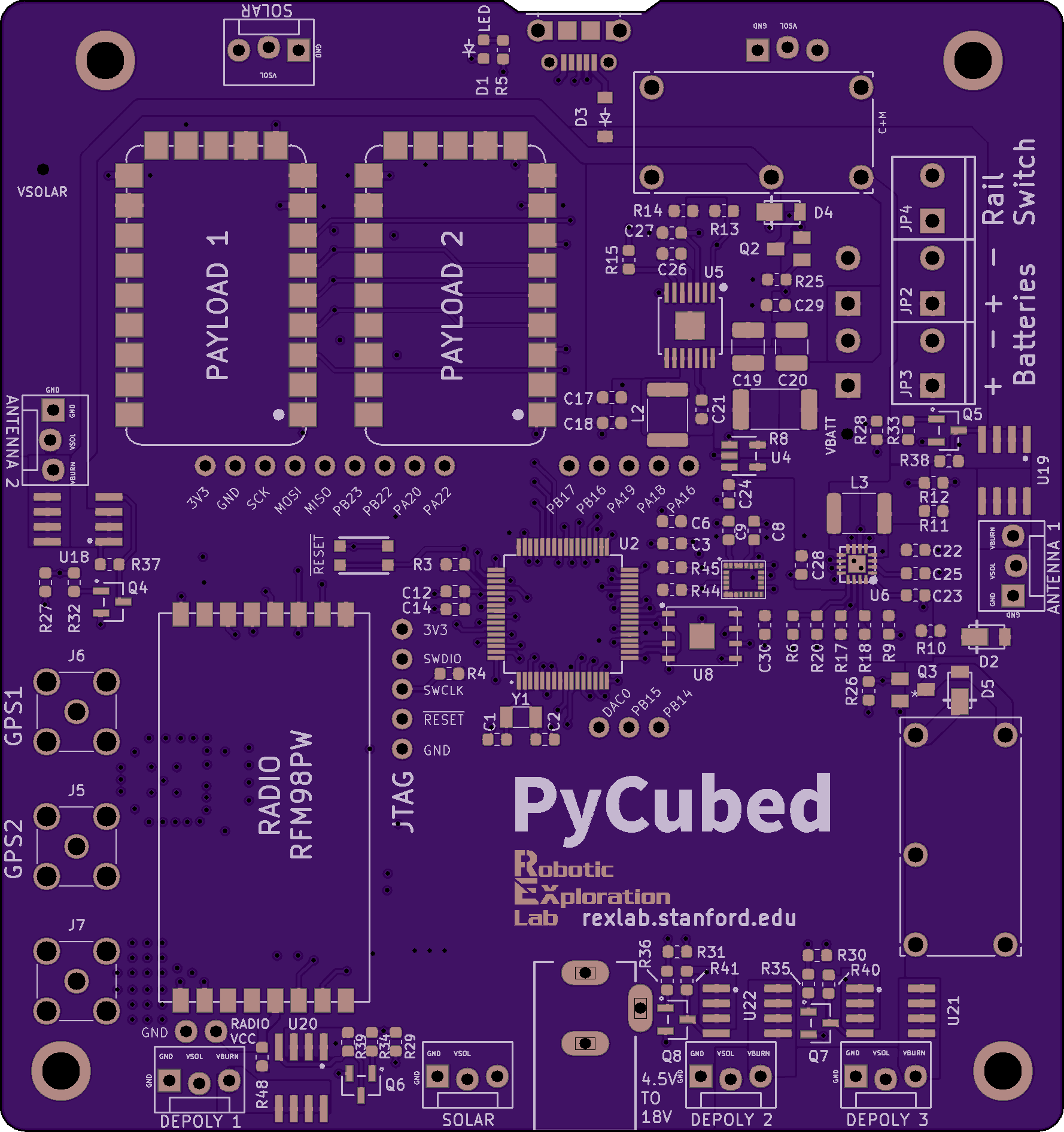

- Component Selection Overload: Modern CubeSats can choose from thousands of COTS components. Evaluating every option manually is impossible. AI systems can autonomously search databases, compare specifications, assess flight heritage, check lead times, and recommend optimal components based on mission requirements.

- Cost Pressure: Nanosatellites compete on affordability. AI reduces engineering hours, minimizes physical prototyping, catches design flaws before hardware is built, and optimizes for manufacturability, all of which drive down costs.

Blackwing Space's Approach: Open, Accessible, and AI

At Blackwing Space, we're integrating AI across our entire operation, but we're doing it differently. While proprietary platforms like MERCURY demonstrate what's possible, our approach aligns with our core principles: open standards, domestic manufacturing, and accessible technology.

We believe AI shouldn't create new vendor lock-in. It should make satellite development more accessible, more transparent, and more adaptable to customer needs.

Generative Design for Structural Optimization

We're using generative design AI to automatically propose lightweight frame designs that meet strength requirements while minimizing mass. Instead of engineers manually iterating through structural configurations, our AI tools explore thousands of design variations simultaneously, suggesting manufacturable structures optimized for specific mission parameters.

The result: lighter frames, faster design cycles, and reduced physical prototyping. More importantly, this technology enables distributed co-design, so that partners, universities, and commercial customers can participate in the design process without needing years of spacecraft engineering experience.

AI-Enhanced Built-In Test Equipment (BITE)

Our spacecraft will feature extensive self-diagnostic capabilities and AI-driven predictive fault recovery.

We're deploying TinyML models directly on our ARM Cortex-M4F flight controllers for real-time anomaly detection. By analyzing voltage, current, temperature, and vibration data with machine learning, our satellites can autonomously trigger safe modes before minor anomalies become mission-ending failures.

The models are small enough to run on resource-constrained spacecraft processors and can be updated via over-the-air commands. As we gather orbital data, the system gets smarter.

Expected impact: 40% reduction in ground monitoring requirements, 6-12 month extension in orbital lifespan, and significantly improved fault tolerance.

Supply Chain Intelligence

Building American-made nanosatellites means managing complex domestic supply chains. We're using machine learning dashboards to predict component lead times, flag potential foreign dependencies, and automate alerts for at-risk suppliers.

These models train on vendor reliability data, cost fluctuations, and historical delivery performance. The system helps us maintain our "Made in USA" commitment while reducing production delays by 20-30%.

Automated Test Data Analysis

Thermal vacuum testing and vibration qualification generate massive datasets. We're applying AI to automatically analyze test results, predict failure correlations before launch, and recommend minimal yet complete test sequences for each mission profile. Less time analyzing data means more time building satellites.

The Competitive Landscape

Proteus Space isn't the only company pursuing AI-enabled satellite design. The technology is appearing across the industry:

- Proprietary Platforms: Companies like Proteus are building closed AI systems optimized for their internal workflows. These platforms deliver impressive speed improvements but create vendor dependencies.

- Component Vendor AI: GOMspace and other suppliers are developing AI tools for component selection and system optimization. These help streamline the supply chain but focus narrowly on product catalogues.

- Constellation Operators: Large constellation companies are using AI for orbital mechanics, collision avoidance, and network optimization, but these tools aren't accessible to smaller operators or custom missions.

Open-Standard Integrators: A smaller group of manufacturers (including Blackwing) is building AI capabilities on open frameworks, making the technology accessible to customers and partners rather than proprietary black boxes.

The American Advantage in AI Satellite Development

There's a strategic dimension to AI adoption in aerospace that goes beyond technical capabilities: data sovereignty and supply chain security.

AI systems require massive training datasets. For satellite design, that means telemetry data, component specifications, supply chain information, mission parameters, and failure analysis. Where that data lives and who controls it matters enormously for ITAR compliance and national security.

Blackwing's AI infrastructure runs exclusively on U.S. cloud platforms with American data residency. Our component databases prioritize domestic suppliers. Our training datasets come from U.S. university missions and American commercial operators.

This isn't just about compliance; it's about building AI systems that strengthen American space capabilities rather than creating new dependencies on foreign technology or foreign-controlled data.

What Comes Next

The following 24 months will see explosive growth in AI adoption across the nanosatellite industry. We expect to see:

- Commercially Available AI Design Tools: Proteus has announced that it'll offer a SaaS version of its MERCURY platform by the end of 2026. Others will follow. The barrier to entry for AI-assisted satellite design is dropping rapidly.

- Edge AI Payloads: Satellites carrying machine learning inference hardware as primary payloads, performing on-orbit data analysis instead of downlinking raw data for ground processing.

- AI-Optimized Constellations: Machine learning systems design optimal orbital configurations, manage inter-satellite links, and autonomously adjust coverage patterns based on demand.

- Automated Assembly Systems: Computer vision and robotics guided by AI performing satellite integration tasks, particularly valuable for high-volume constellation builds.

- Predictive Mission Planning: AI systems that analyze historical mission data to recommend optimal launch windows, orbital parameters, and operational strategies before design even begins.

Getting It Right

The race to automate satellite design isn't just about speed. It's about maintaining quality, ensuring reliability, and preserving the engineering judgment that keeps missions successful.

AI is a tool, not a replacement for aerospace expertise. The companies that succeed will be those that use artificial intelligence to amplify human engineers handling the tedious optimization work, searching vast design spaces, and catching errors while keeping experienced professionals in the decision-making loop.

At Blackwing, every AI-generated design still gets reviewed by our engineering team. Every component recommendation gets validated against our flight heritage database. Every optimization suggestion gets tested against real-world manufacturing constraints.

The goal isn't to remove humans from the process. It's to let them focus on the problems that actually require human creativity, intuition, and judgment.

The Accessible Future

Proteus Space proved that AI can compress satellite development timelines from years to months. That's remarkable, and they deserve credit for demonstrating what's possible.

But the real revolution happens when that capability becomes accessible, when universities can use AI design tools to optimize their student CubeSats, when startups can leverage machine learning for component selection without million-dollar software licenses, when small commercial operators can deploy digital twins without hiring data scientists.

That's the future we're building at Blackwing Space: AI-enhanced satellite development that's open, affordable, and American-made. Not as a proprietary advantage, but as a capability we can share with customers, partners, and the broader space community.

The world's first AI-designed satellite just launched. The next thousand are already in development. And the best part? We're just getting started.