PEEK in CubeSat Design: When High-Performance Polymers Beat Aluminum

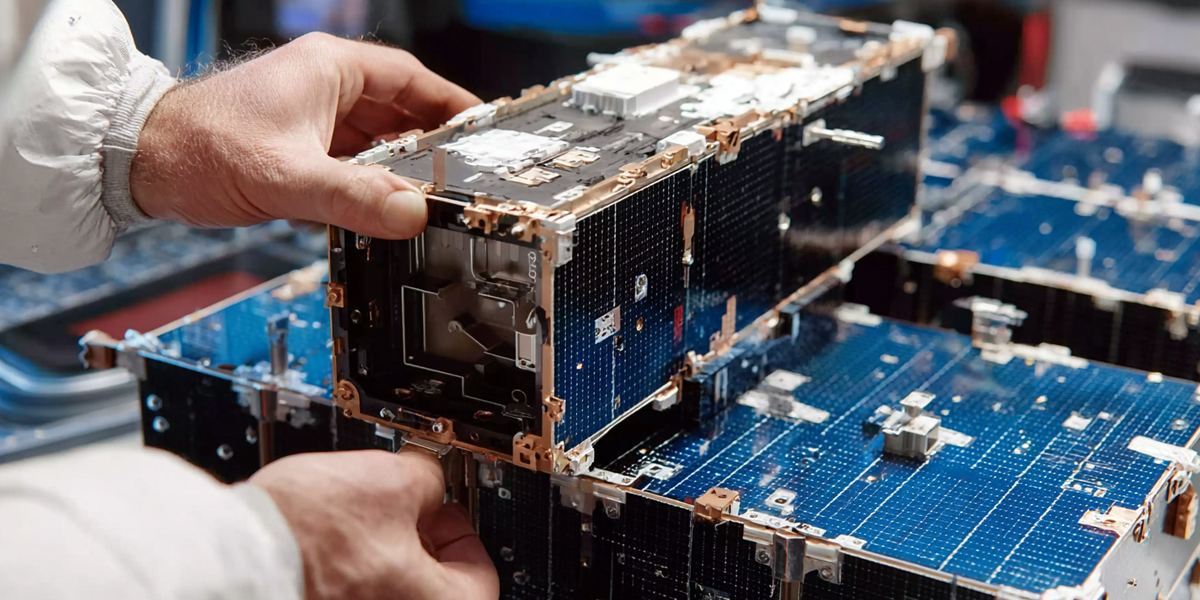

When most aerospace engineers think about structural materials for satellites, aluminum immediately comes to mind. It has been the workhorse of spacecraft design for decades, offering a well-understood combination of strength, machinability, and thermal properties. But as CubeSat platforms become more sophisticated and mission requirements more demanding, a growing number of designers are discovering situations where polyetheretherketone, better known as PEEK, offers compelling advantages over traditional aluminum structures.

At Blackwing Space, we have been carefully evaluating PEEK for specific applications in our modular nanosatellite platforms, particularly where thermal management and mass optimization create system-level benefits that justify the material's higher upfront cost. Understanding when to choose PEEK over aluminum is not about following trends but about making informed engineering decisions based on your mission's specific requirements.

Understanding PEEK: More Than Just Another Plastic

PEEK belongs to a class of materials called high-performance thermoplastics, and calling it "just plastic" would be like calling titanium "just metal." The material's full chemical name, polyetheretherketone, describes its molecular structure, which features repeating ether and ketone groups that create exceptional thermal and chemical stability. What matters for satellite designers is how these molecular characteristics translate into real-world performance in the space environment.

The material maintains its mechanical properties across a temperature range from approximately negative one hundred degrees Celsius to positive two hundred fifty degrees Celsius. This thermal stability is particularly valuable in low Earth orbit, where a CubeSat's exterior surfaces can swing from minus one hundred degrees Celsius in Earth's shadow to positive one hundred twenty degrees Celsius in direct sunlight over the course of a single ninety-minute orbit. Unlike many polymers that become brittle at cryogenic temperatures or soften when heated, PEEK maintains consistent mechanical behavior throughout these thermal cycles.

Perhaps more importantly for space applications, PEEK exhibits extremely low outgassing in vacuum conditions. When materials are exposed to the vacuum of space, volatile compounds trapped within their structure can be released, a process known as outgassing. These released compounds can condense on optical surfaces, contaminate sensitive instruments, or create small but measurable forces on the spacecraft. PEEK's outgassing characteristics meet NASA's stringent requirements for spacecraft materials, with total mass loss typically well below one percent and collected volatile condensable materials under point one percent when tested according to ASTM E595 standards.

The Traditional Case for Aluminum

Before diving into where PEEK excels, it is worth understanding why aluminum has been so dominant in CubeSat design. The material offers several characteristics that are difficult to beat for primary structures. Aluminum alloys, particularly 6061-T6 and 7075-T6, provide excellent strength-to-weight ratios with yield strengths in the range of two hundred seventy to five hundred megapascals. The material is also readily machinable with standard CNC equipment, widely available from numerous suppliers, and comes at a relatively low cost per kilogram.

From a thermal perspective, aluminum's high thermal conductivity of approximately one hundred sixty to two hundred watts per meter-kelvin makes it excellent for spreading heat across structures and radiating it away. This is why most CubeSat chassis are built from aluminum, they naturally help distribute heat from electronics throughout the structure and then radiate it to space. The material's thermal expansion coefficient is well-characterized and reasonably low at about twenty-three parts per million per degree Celsius, which helps maintain dimensional stability across thermal cycles.

For standard CubeSat applications where the chassis serves primarily as a structural box to hold components and meet deployment requirements, aluminum remains an excellent and cost-effective choice. Blackwing Space uses aluminum extensively in our standard chassis designs precisely because it delivers reliable performance at an accessible price point, which aligns with our mission to make space more accessible through affordable platforms.

Where PEEK Changes the Equation

The decision to use PEEK instead of aluminum becomes compelling in specific applications where the material's unique properties create system-level advantages. Understanding these scenarios helps designers make informed trade-offs between material costs and overall mission performance.

Thermal Isolation and Management

One of the most powerful applications of PEEK in CubeSat design involves thermal isolation. While aluminum's high thermal conductivity is beneficial for spreading heat, there are many situations where you explicitly want to prevent heat transfer between components. PEEK's thermal conductivity is only about point two five watts per meter-kelvin, roughly eight hundred times lower than aluminum. This dramatic difference allows PEEK components to act as highly effective thermal breaks.

Consider a scenario common in Earth observation satellites where you have an imaging sensor that needs to remain at a stable, relatively cool temperature to minimize dark current noise, but this sensor is mounted near electronics that generate several watts of heat. Using aluminum standoffs or mounting brackets would create a thermal short circuit, forcing your thermal control system to work much harder to maintain the sensor temperature. By substituting PEEK standoffs or mounting interfaces, you can dramatically reduce the thermal coupling between these components.

Blackwing Space is incorporating PEEK thermal isolation components in our payload mounting interfaces specifically to address this challenge. By using PEEK standoffs and isolators in strategic locations, we can reduce the thermal management burden on the overall system, which in turn reduces power requirements and extends mission life. The few grams of PEEK used in these interfaces can save tens of watts of power that would otherwise be consumed by active cooling systems.

Mass Reduction in Non-Primary Structures

While PEEK's density of approximately one point three grams per cubic centimeter is actually higher than aluminum's two point seven grams per cubic centimeter might suggest aluminum is lighter, the story changes when you consider strength-to-weight ratios for specific geometries and loading conditions. PEEK's tensile strength of around ninety to one hundred megapascals is lower than aluminum's, but for certain component geometries, particularly those dominated by compressive loads or where buckling is not a concern, PEEK can deliver equivalent performance at lower mass.

Fasteners and standoffs represent a particularly interesting case study. A typical three-unit CubeSat might use one hundred or more fasteners and standoffs throughout its structure. While each individual component might save only a gram or two by switching from aluminum to PEEK, the cumulative effect across an entire spacecraft can be significant. More importantly, PEEK fasteners eliminate the need for lock-wiring or thread-locking compounds in many applications due to their excellent vibration resistance and the slight compliance of the material.

Eliminating Lubrication Requirements

PEEK exhibits excellent tribological properties, meaning it has low friction and good wear resistance even without lubrication. This characteristic becomes valuable in deployment mechanisms, hinge assemblies, and any other moving parts on a CubeSat. In the vacuum of space, conventional lubricants can evaporate or migrate away from bearing surfaces, leading to increased friction and potential mechanism failure. PEEK components, particularly when filled with materials like carbon fiber or PTFE, can operate successfully without any lubrication.

For our deployable systems at Blackwing Space, we are evaluating PEEK for hinge pins and bearing surfaces in antenna and solar panel deployment mechanisms. The material's self-lubricating properties eliminate one potential failure mode and simplify the design by removing the need for lubricant retention features or careful material selection to prevent cold welding in vacuum.

Chemical and Radiation Resistance

While not always a primary consideration for CubeSats in low Earth orbit, PEEK's exceptional chemical resistance and moderate radiation tolerance can be valuable in certain mission profiles. The material is essentially inert to most chemicals and solvents, which simplifies handling and processing. Unlike aluminum, which can corrode in certain environments or react with some propellants, PEEK maintains its properties when exposed to a wide range of chemicals.

For missions involving propulsion systems or chemical sensors, PEEK components can often be placed in direct contact with propellants or reactive chemicals without degradation. The material's radiation resistance, while not matching that of metals for very high radiation environments, is adequate for most low Earth orbit missions and significantly better than many other polymers.

The Engineering Trade-Offs

Choosing PEEK over aluminum is never a simple decision because every engineering choice involves trade-offs. Understanding these trade-offs helps designers make informed decisions rather than simply following material trends.

Cost Considerations

The most obvious trade-off is cost. PEEK raw material can cost ten to twenty times more than aluminum on a per-kilogram basis, and machining costs are often higher as well due to the material's toughness and the need for specialized tooling. For a startup or university team working with a limited budget, this cost difference can be prohibitive for widespread use.

However, the cost equation becomes more nuanced when you consider system-level effects. If using PEEK thermal isolators allows you to eliminate or downsize active thermal control systems, the overall system cost might actually decrease despite the higher material cost for those specific components. At Blackwing Space, we focus on this system-level optimization, using PEEK only where it provides clear benefits that justify the additional expense while maintaining our commitment to affordable, accessible satellite platforms.

Mechanical Strength Limitations

PEEK's lower absolute strength compared to aluminum means it cannot simply be substituted in all applications. Primary load-bearing structures, particularly those subject to high launch loads, generally remain the domain of aluminum or titanium. PEEK is better suited for secondary structures, mounting interfaces, and components where its other properties provide specific advantages beyond pure mechanical strength.

The material's modulus of elasticity, around three point six gigapascals, is significantly lower than aluminum's seventy gigapascals. This means PEEK components will deflect more under load, which can be problematic for applications requiring high stiffness. Designers must carefully analyze whether the additional deflection is acceptable for their specific application or whether it could lead to misalignment of optical systems, interference between components, or other issues.

Manufacturing and Processing

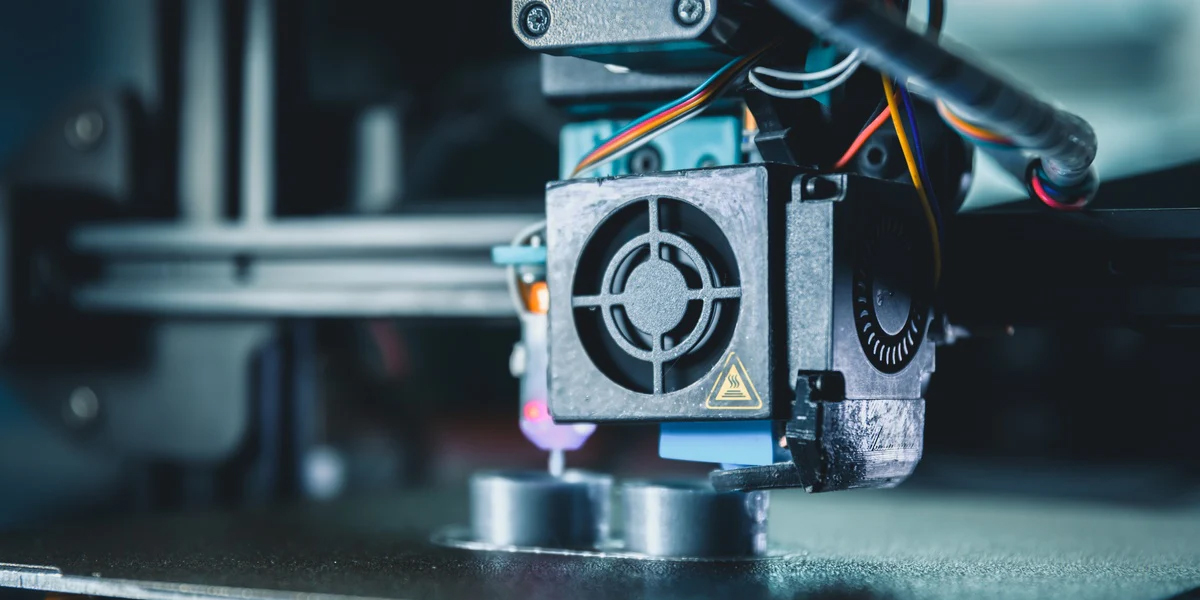

PEEK requires different manufacturing approaches than aluminum. While both can be machined, PEEK's toughness wears cutting tools more quickly and generates stringy chips that can be challenging to manage. The material can also be injection molded, which offers opportunities for complex geometries and integrated features, but molding requires significant upfront investment in tooling.

For small-scale production typical of CubeSat platforms, machining from stock material is usually more economical than molding. However, the machining process requires attention to cutting speeds, feed rates, and tool selection to avoid melting the material or generating excessive heat. At Blackwing Space, we are developing relationships with manufacturing partners who have specific expertise in machining high-performance polymers to ensure consistent quality in our PEEK components.

Practical Design Guidelines

Based on our development work and analysis of successful CubeSat missions, several practical guidelines emerge for when to consider PEEK in your design.

First, identify thermal isolation requirements early in your design process. If you have components with widely different optimal operating temperatures, PEEK interfaces between them may be worthwhile even if they cost more than aluminum. The power savings from reduced active thermal control often justify the material expense.

Second, consider PEEK for components where its self-lubricating properties eliminate complexity or failure modes. Deployment mechanisms, particularly those that must remain dormant for months or years before activation, benefit from materials that do not rely on lubricants that might degrade or migrate over time.

Third, use PEEK strategically rather than uniformly. A common mistake is attempting to build an entire structure from PEEK to maximize its benefits. Instead, use PEEK where it solves specific problems and use aluminum or other materials where they are more appropriate. This hybrid approach optimizes both performance and cost.

Fourth, verify that your thermal analysis properly accounts for PEEK's low thermal conductivity. Components mounted on PEEK standoffs will have limited thermal coupling to the chassis, which means they must be able to radiate heat directly to space or have alternative thermal paths. Failing to account for this can lead to overheating of isolated components.

Material Properties Comparison

The following table summarizes key properties relevant to CubeSat design, comparing PEEK with common aluminum alloys. These values are typical and can vary based on specific grades and processing conditions, so always verify properties with your material supplier for critical applications.

Property

PEEK

Aluminum 6061-T6

Significance for CubeSats

Density (g/cm³)

1.30

2.70

PEEK appears lighter but lower strength means larger sections often needed

Tensile Strength (MPa)

90-100

270-310

Aluminum significantly stronger for primary structures

Elastic Modulus (GPa)

3.6

69

PEEK deflects much more under load, important for optical alignment

Thermal Conductivity (W/m·K)

0.25

167

PEEK provides thermal isolation, aluminum spreads heat

CTE (ppm/°C)

47

23.6

PEEK expands more with temperature, affects precision assemblies

Operating Temperature (°C)

-100 to +250

-200 to +200

Both adequate for LEO thermal environment

Outgassing TML (%)

<0.5

<0.1

Both meet spacecraft requirements, PEEK slightly higher

Relative Cost

10-20x

1x

PEEK significantly more expensive per kilogram

Real-World Applications and Flight Heritage

While PEEK is still emerging in CubeSat applications compared to its extensive use in larger spacecraft, several successful missions have demonstrated its value. Various Earth observation CubeSats have used PEEK thermal isolators to maintain camera sensor temperatures with minimal power consumption. Communications satellites have employed PEEK in waveguide components and antenna feed systems where low thermal conductivity prevents thermal distortion of precisely tuned structures.

The material has even more extensive flight heritage in larger spacecraft, where it appears in everything from wire insulation to structural components to bearing surfaces in mechanisms. This heritage provides confidence in the material's long-term behavior in the space environment, though designers should always verify that specific PEEK grades and processing methods have appropriate qualification data for their application.

Technical Note: When sourcing PEEK for space applications, verify that the specific grade has been tested for outgassing according to ASTM E595 or equivalent standards. Not all commercial PEEK formulations meet spacecraft requirements, particularly filled grades that may contain additives with higher outgassing characteristics.

The Blackwing Space Approach

At Blackwing Space, our philosophy toward materials selection reflects our broader mission of making space accessible through affordable, modular platforms built with automotive-grade American-made components. We see PEEK not as a wholesale replacement for aluminum but as a strategic tool in our design toolkit that allows us to optimize specific subsystems.

Our modular architecture approach means that payload developers can choose thermal interfaces and mounting systems based on their specific requirements. For payloads with modest thermal management needs, our standard aluminum interfaces provide excellent performance at minimum cost. For missions requiring thermal isolation, precision temperature control, or minimum mass mounting systems, we offer PEEK-based alternatives that integrate seamlessly with our standard chassis.

This flexibility allows universities and commercial customers to optimize their satellite platforms for their specific mission requirements without being forced into one-size-fits-all solutions. A university team developing an Earth observation mission can select PEEK thermal isolators for their camera while using standard aluminum structures everywhere else, paying the premium only where it delivers clear value.

We are also developing design guidelines and analysis tools to help our customers make informed decisions about when PEEK provides benefits worth its cost. Part of democratizing access to space involves empowering teams with the knowledge to make smart engineering trade-offs rather than simply following conventional wisdom or the latest material trends.

Looking Forward: PEEK in Next-Generation Platforms

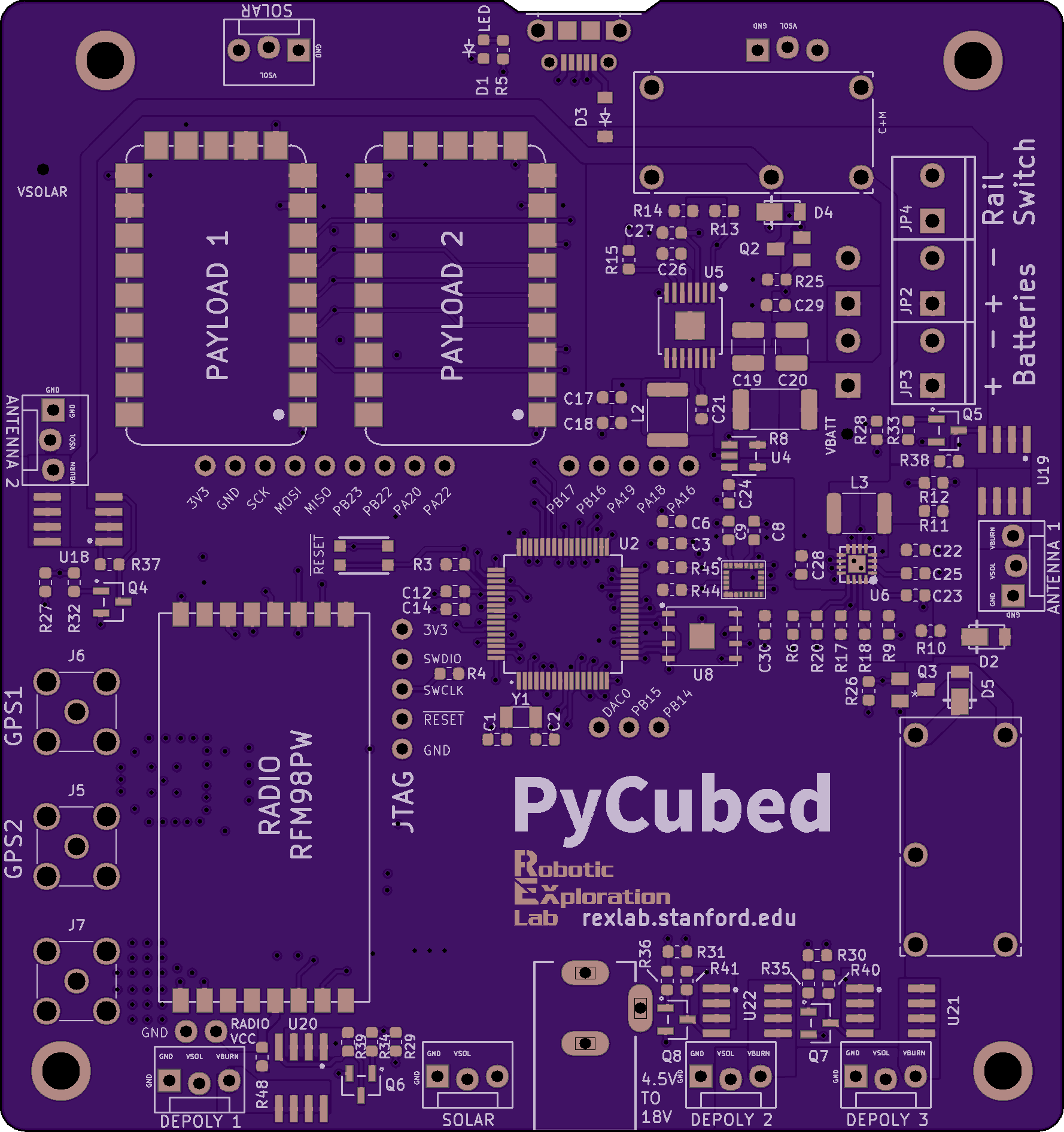

As we develop our next-generation nanosatellite platforms, PEEK components are becoming increasingly integrated into our standard offerings. We are particularly focused on three areas where the material provides the clearest advantages for our customer base.

First, standardized payload mounting interfaces with integrated thermal isolation allow payload developers to assume predictable thermal environments without requiring extensive thermal analysis. Second, deployment mechanism components that eliminate lubrication requirements and simplify ground handling procedures reduce both cost and risk for complex missions. Third, modular thermal management assemblies that can be configured based on mission-specific power dissipation requirements provide flexibility without requiring custom design work.

By incorporating these PEEK components into our modular architecture, we can offer sophisticated thermal management capabilities that were previously available only on much more expensive satellite platforms. This aligns perfectly with our goal of bringing enterprise-grade capabilities to the emerging Space 3.0 ecosystem at price points accessible to universities, startups, and commercial operators.

Making the Decision: A Framework

For designers evaluating whether to use PEEK in their CubeSat, consider working through the following decision framework. Begin by identifying specific technical challenges in your design where conventional materials create problems or limitations. Common examples include thermal coupling between components at different temperatures, deployment mechanisms requiring lubrication, or mass constraints in secondary structures.

Next, quantify the system-level impact of using PEEK to address these challenges. For thermal isolation applications, calculate the power savings from reduced active thermal control requirements. For deployment mechanisms, consider the reduced testing requirements and improved reliability from eliminating lubricants. For mass reduction, evaluate whether the weight savings enable additional payload capacity or extended mission life.

Then perform a cost-benefit analysis that includes both direct material costs and indirect system effects. A PEEK component that costs one hundred dollars more than an aluminum equivalent might seem expensive until you realize it eliminates a two hundred dollar thermoelectric cooler and reduces power requirements enough to decrease solar panel size. The system-level perspective often reveals that PEEK can be cost-effective even when individual components appear expensive.

Finally, verify that you have access to appropriate manufacturing capabilities and that your design properly accounts for PEEK's material properties, particularly its lower stiffness and higher thermal expansion compared to aluminum. Consulting with experienced manufacturers early in the design process can prevent costly mistakes and ensure that your PEEK components can be produced with acceptable quality and lead times.

Conclusion: Strategic Material Selection for Mission Success

The choice between PEEK and aluminum in CubeSat design is not about one material being universally better than the other. Rather, it is about understanding the specific requirements of your mission and selecting materials that optimize performance, cost, and risk for your particular application. Aluminum remains an excellent choice for primary structures, thermal spreading, and applications where its high strength and stiffness are essential. PEEK shines in thermal isolation applications, deployment mechanisms, and situations where its unique combination of properties solves problems that would be difficult or expensive to address with conventional materials.

At Blackwing Space, we are committed to providing our customers with both the technology and the knowledge to make informed materials decisions. Our modular platform architecture allows you to use PEEK where it makes sense for your mission without forcing you to use it everywhere. As space becomes increasingly accessible and CubeSat missions become more sophisticated, understanding when high-performance polymers beat traditional metals becomes essential to achieving mission success within realistic budgets.

The future of small satellite design likely involves hybrid approaches that use the best material for each specific application rather than adhering rigidly to conventional material choices. By carefully evaluating trade-offs and focusing on system-level optimization, designers can create CubeSat platforms that deliver exceptional performance at accessible price points, bringing sophisticated space capabilities to the growing community of universities, startups, and commercial operators driving the Space 3.0 revolution.

About Blackwing Space: Blackwing Space is a Nashville-based aerospace company developing affordable, modular nanosatellite platforms using American-made automotive-grade components. Our mission is to make space accessible to universities, startups, and commercial operators through sophisticated technology at realistic price points. Learn more about our platforms and capabilities at our website or contact us to discuss your mission requirements.