Understanding Mass Budgets: Why Your Payload's Weight Matters

You've chosen your Blackwing platform based on payload volume. Great! But there's another critical constraint that can make or break your mission: mass.

Launch providers don't just care about how much volume your satellite takes up—they care about how much it weighs, too. And if you underestimate your payload's mass early in the design process, you'll either face expensive overages at launch or need to redesign your entire mission.

Let's talk about how to get your mass budget right from day one.

Why Mass Matters in Space

Every gram counts when you're launching to orbit. Launch providers assign a maximum allowable mass for each CubeSat slot and charge premium rates for any overage. Miss your mass target by even a few hundred grams, and you could be looking at thousands of dollars in additional costs—or worse, being bumped from your manifest entirely.

For Blackwing platforms, here's what you're working with:

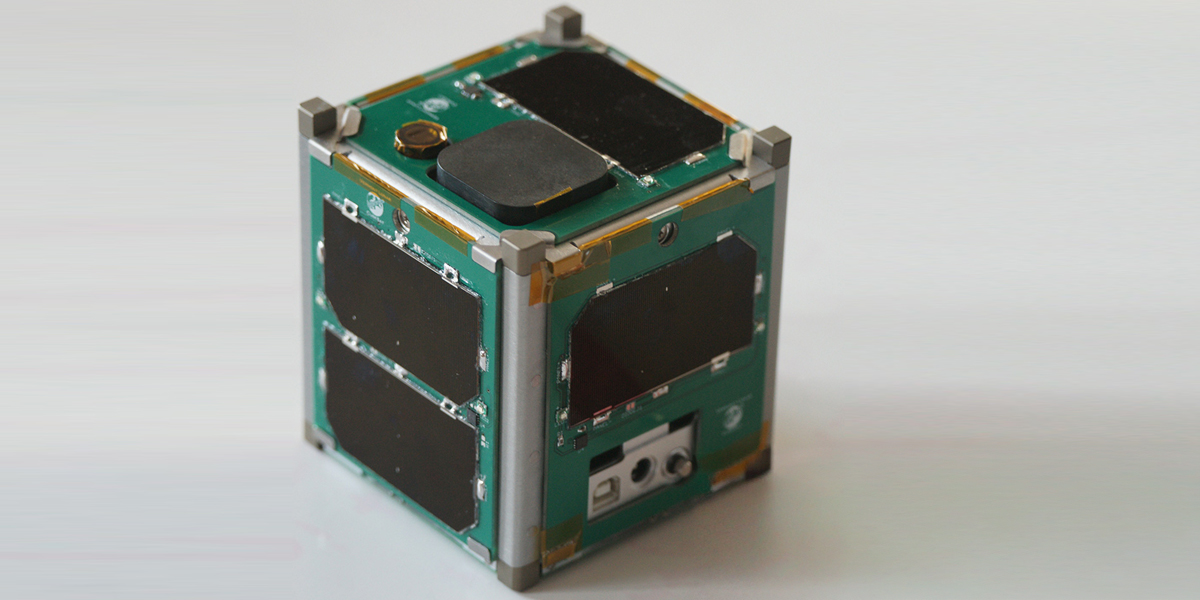

- Sparrow (1U): Up to 1 kg payload mass

- Kestrel (3U XL): Up to 4 kg payload mass

- Osprey (6U XL): Up to 8 kg payload mass

These aren't aspirational numbers—they're hard limits that account for the platform's structure, power systems, communications, attitude control, and thermal management. Your payload needs to fit within these allocations.

The Mass Growth Problem

Here's the challenge: early in your design, you don't know exactly what everything will weigh. That camera module? The datasheet says 180 grams, but what about the mounting bracket? The wiring harness? The thermal interface material? The conformal coating on the PCB?

And here's the uncomfortable truth: hardware always gets heavier during development. Always.

You start with vendor specs and CAD estimates. Then you add fasteners. Then you realize you need more shielding. Then the thermal analysis says you need a thicker baseplate. Then you add margin for manufacturing tolerances. Before you know it, your "200-gram payload" weighs 340 grams.

This is called mass growth, and it's why experienced spacecraft engineers use Mass Growth Allowance (MGA).

Understanding Mass Growth Allowance

Mass Growth Allowance is reserved margin—extra mass you allocate in your budget to account for the inevitable weight gain as your design matures. It's not pessimism; it's reality-based planning.

The aerospace industry has studied this phenomenon extensively, and the AIAA S-120A-2020 standard provides clear guidelines on how much MGA to allocate based on your design maturity level:

- Early Concept (Pre-Phase A): 50-100% MGA. You're sketching ideas. Allocate at least half your estimated mass as growth allowance, potentially doubling your budget.

- Preliminary Design (Phase A/B): 30-50% MGA. You have a conceptual design and are selecting components. Your estimates are better, but significant unknowns remain.

- Detailed Design (Phase C): 20-30% MGA. CAD models exist, components are specified, and you're working out the integration details. Mass estimates are solidifying.

- Final Design (Phase D): 10-20% MGA. You're in fabrication and assembly. Most components are procured and measured. Only minor changes expected.

- As-Built (Post-Delivery): 0-5% MGA. Hardware is complete. You're accounting only for measurement uncertainty and potential late additions.

How to Calculate Your Mass Budget

Let's walk through a practical example. Say you're developing an earth observation payload for the Kestrel platform.

Step 1: List all payload components (interior and exterior).

- Camera module: 180g

- Optics assembly: 220g

- Electronics board: 95g

- Mounting structure: 140g

- Thermal hardware: 60g

- Wiring harness: 35g

- External baffle: 85g

- Connectors and fasteners: 45g

- Subtotal: 860g

Step 2: Determine your design maturity. You're in preliminary design (Phase A/B), so AIAA S-120A recommends 30-50% MGA. Let's use 40%.

Step 3: Calculate MGA. 860g × 0.40 = 344g growth allowance.

Step 4: Calculate total estimated mass. 860g + 344g = 1,204g (1.2 kg)

Your payload fits comfortably within the Kestrel's 4 kg allocation, with plenty of room to spare for late additions or design changes.

What Counts as Payload Mass?

When calculating your payload mass budget, include everything that isn't part of the base Blackwing platform:

Interior components:

- Circuit boards and electronics

- Processors and memory

- Sensors and detectors

- Mechanical housings and structures

- Thermal interfaces and heatsinks

- Internal cabling and connectors

Exterior components:

- Antennas and RF hardware

- External sensors (star trackers, sun sensors)

- Optical elements (lenses, baffles, windows)

- Deployment mechanisms

- External mounting hardware

If it's custom to your mission, it counts as payload mass.

Real-World Advice: Start Conservative

Here's what 60+ years of spaceflight experience has taught us: it's better to have MGA you don't use than to need MGA you don't have.

If you're in early design and think your payload will weigh 2 kg, budget for 3 kg. Future you—the one scrambling to shave off grams three weeks before integration—will be immensely grateful. You can always release MGA as your design matures and mass estimates improve, but you can't conjure it out of thin air when you need it.

And remember: launch providers charge for mass overages. That extra 200 grams of "we'll figure it out later" could cost you $4,000-$10,000 at typical rideshare rates. The 30 minutes you spend creating a proper mass budget today will save you headaches and money tomorrow.

Blackwing Platform-Specific Guidelines

For Sparrow missions (1 kg payload): With limited mass available, every gram counts. If you're in early design and your estimates approach 700-800g, consider whether Kestrel might give you more breathing room. Don't paint yourself into a corner.

For Kestrel missions (4 kg payload): This is the sweet spot for most missions. You have enough margin to accommodate reasonable mass growth without excessive cost. Use your MGA wisely—it's there for real engineering needs, not scope creep.

For Osprey missions (8 kg payload): More capability means more complexity, which often means more mass growth. If you're flying multiple instruments or novel technology, seriously consider using 50% MGA in early phases. Complex payloads have more ways to gain weight.

Moving Forward with Confidence

Getting your mass budget right isn't about perfect prediction—it's about honest estimation and disciplined margin management. Use AIAA S-120A guidelines, track your mass throughout development, and hold regular mass budget reviews as your design matures. At Blackwing Space, we've sized our platforms to give you real usable payload capacity. We've done the systems engineering so you know exactly what you have to work with. Now it's your turn to manage that allocation wisely.

Next up: We'll explore power budgets and how to ensure your payload has the energy it needs to accomplish its mission in orbit.