Where to Buy PyCubed: Commercial Availability, Pricing, and the Future of Open Source Satellite Computing

Everything you need to know about purchasing PyCubed-based flight computers for your CubeSat mission

The Rise of PyCubed as the De Facto CubeSat Flight Computer

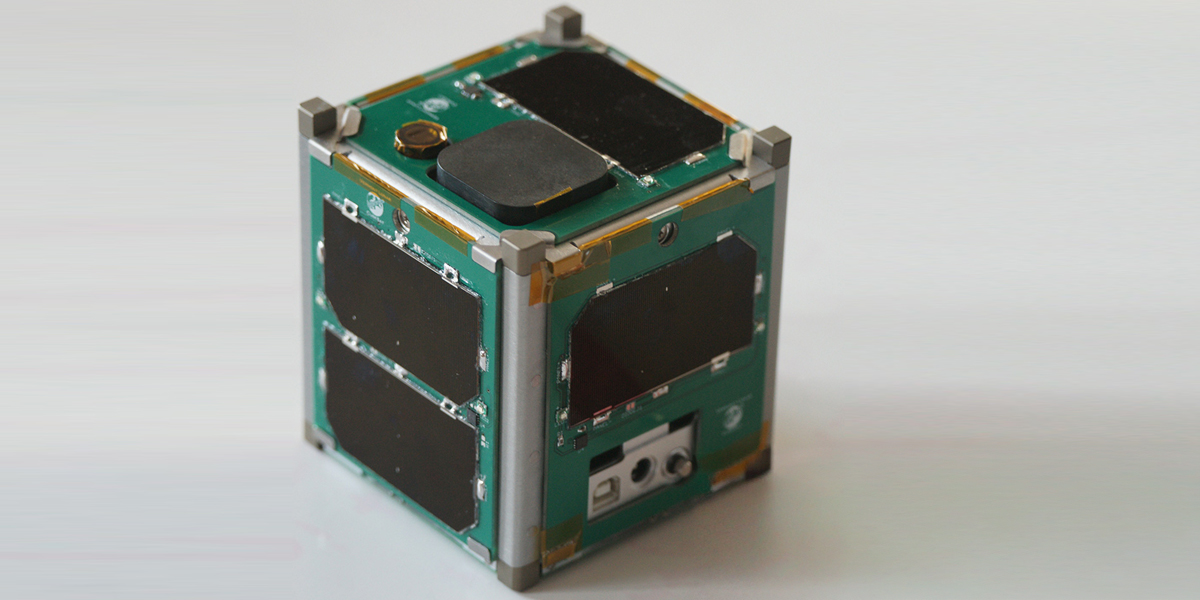

If you're researching CubeSat onboard computers, you've almost certainly encountered PyCubed. Originally developed at Stanford University by Max Holliday and the Space Sciences team, PyCubed has become one of the most successful open source satellite platforms ever created - and for good reason.

PyCubed represents a fundamental shift in how small satellites are built. By leveraging CircuitPython and modern COTS (commercial off-the-shelf) components, it offers capabilities that previously required expensive custom electronics at a fraction of the cost. The platform is fully open source, extensively documented, and has been validated through actual space missions.

But here's the challenge many teams face: where do you actually buy a PyCubed board?

Understanding PyCubed: What Makes It Special

Before diving into purchasing options, it's worth understanding why PyCubed has achieved such widespread adoption in the CubeSat community.

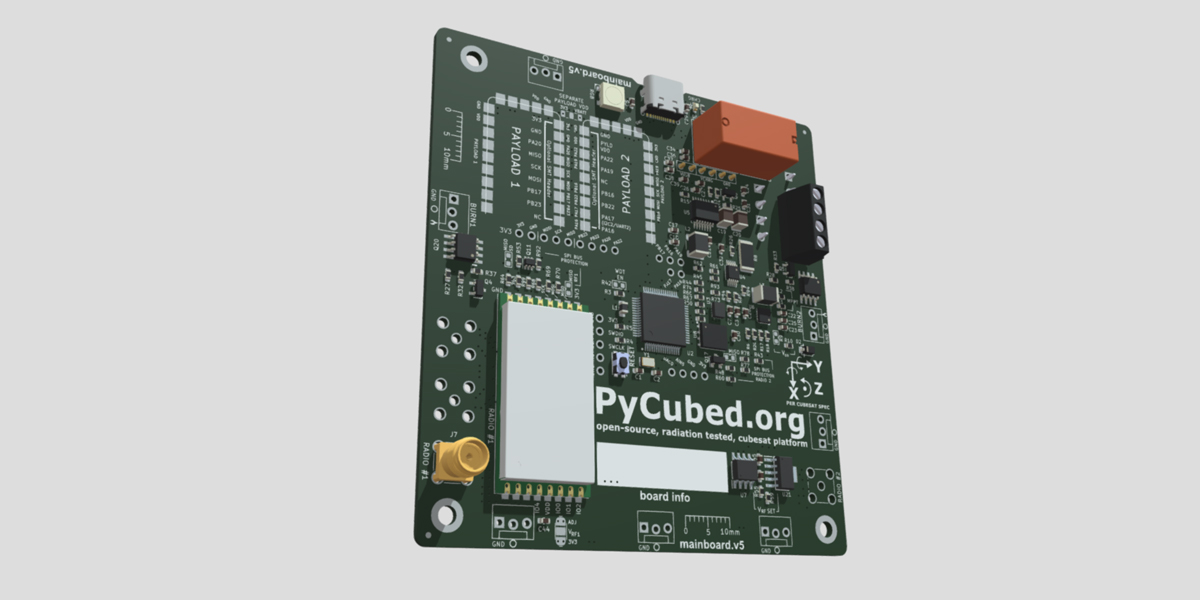

CircuitPython-Based Development: Unlike traditional satellite flight software written in C or assembly, PyCubed runs CircuitPython - a version of Python optimized for microcontrollers. This dramatically lowers the barrier to entry for university teams and startups who can develop and test satellite code without specialized embedded systems expertise.

Integrated Subsystems: A single PyCubed board integrates functions that traditionally required multiple separate boards: power management, attitude determination and control, communications interfaces, data storage, and computing. This integration saves mass, volume, power, and complexity.

Radiation Tolerance: PyCubed uses the ATSAMD51 microcontroller, which while not radiation-hardened, has demonstrated surprising resilience in LEO environments. The architecture includes watchdog timers, redundant storage, and error detection mechanisms that provide practical radiation tolerance for most university and commercial missions.

Proven Flight Heritage: This isn't vaporware - PyCubed and its variants have flown on multiple missions including Alba Orbital launches, university satellites, and commercial platforms.

PyCubed Adoption: Real Missions Using the Platform

The question "is PyCubed proven?" has a clear answer: yes. Here are some notable missions:

PyCubed-1: The original demonstration mission launched by Stanford, validating the core platform architecture in orbit.

PROMETHEUS-1: A collaborative mission between Carnegie Mellon University Portugal, Universidade do Minho, and Instituto Superior Técnico. This 1P PocketQube launched in January 2025 specifically to test and validate the PyCubed-Mini platform - a miniaturized variant designed for ultra-small satellites.

Multiple University Missions: Teams at universities worldwide have adopted PyCubed for their satellite projects, attracted by the combination of capability, documentation, and cost-effectiveness.

Commercial Adopters: Several commercial satellite developers have based their platforms on PyCubed architecture, recognizing the value of standing on proven foundations rather than reinventing basic functionality.

The PyCubed community has grown to include hundreds of developers, with active forums, regular updates, and a wealth of shared knowledge. When you choose PyCubed, you're not just getting hardware - you're joining an ecosystem.

The DIY Challenge: Why Building Your Own PyCubed Is Harder Than It Looks

PyCubed is open source, with full schematics, board layouts, and bills of materials available on GitHub. Theoretically, anyone can manufacture their own boards. In practice, most teams discover this is significantly more challenging than expected.

Component Obsolescence and Availability

The original PyCubed design uses components that were readily available in 2019-2020. Fast forward to 2024-2025, and many of these parts are either obsolete, on extended lead times, or only available from questionable suppliers.

The global chip shortage affected PyCubed development significantly. Key components like specific IMU sensors, power management ICs, and even the ATSAMD51 microcontroller itself have experienced availability issues. Teams attempting DIY fabrication often find themselves:

- Waiting 6-12 months for critical components

- Paying 3-5x the original BOM cost due to shortages

- Receiving counterfeit or out-of-spec parts from gray market suppliers

- Redesigning portions of the board to accommodate substitute components

This isn't just inconvenient - it can derail mission timelines and budgets entirely.

PCB Fabrication Complexity

PyCubed uses a 4-layer PCB with fairly tight tolerances. While not exotic by commercial standards, it's beyond what most university fab labs can produce. Teams need to work with professional PCB manufacturers, which introduces:

- Minimum order quantities (often 5-10 boards when you only need 1-2)

- Setup fees that make single-board production expensive

- Quality control challenges with overseas manufacturers

- Shipping delays and customs complications

Assembly and Soldering Challenges

PyCubed features fine-pitch BGA (ball grid array) components, 0402 passives, and complex routing. Hand-assembly is possible for experienced technicians but extremely time-consuming and error-prone. Mistakes are costly:

- A single bridged solder joint can destroy an expensive microcontroller

- Improper thermal profiles during reflow can damage components

- Without X-ray inspection, BGA joints are difficult to verify

Professional assembly services exist, but add significant cost - often $200-500 per board on top of component and PCB costs.

Testing and Validation

Once you've assembled a PyCubed board, how do you know it works correctly? Proper validation requires:

- Functional testing of all subsystems (power, sensors, communications, storage)

- Environmental testing (thermal cycling, vibration)

- Radiation testing for mission-critical applications

- Burn-in periods to catch infant mortality failures

Most university teams lack the equipment and expertise for comprehensive testing. Commercial satellite developers need traceable test data for their quality systems, something DIY boards can't provide.

Documentation and Support Gaps

While PyCubed is well-documented by open source standards, DIY builders frequently encounter issues that aren't covered in the existing documentation:

- Undocumented workarounds for component substitutions

- Firmware bugs that only appear with specific hardware revisions

- Integration issues with particular radio modules or sensors

- Power consumption anomalies under certain operating modes

The community can help, but response times vary and there's no guaranteed support. For mission-critical projects, this uncertainty is problematic.

The True Cost of DIY PyCubed

Let's break down what building your own PyCubed actually costs:

- Components: $150-300 depending on availability and whether you're buying excess inventory

- PCB Fabrication: $100-250 for a small batch (5-10 boards)

- Assembly: $0 (DIY, but 10-20 hours of skilled labor) or $200-500 (professional)

- Testing Equipment: $500-2000 if you don't already have proper tools

- Failed Boards: Budget 30-50% failure rate for first-time builders = additional $100-200

- Engineering Time: 40-80 hours for component sourcing, assembly, testing, and debugging

- Realistic Total: $800-1500 for a single working board, plus 2-4 months of calendar time

And that's assuming everything goes reasonably well. Teams often discover that their "cost-saving" DIY approach actually consumed far more resources than purchasing commercial hardware would have.

PyCubed-Mini: An Even More Challenging Build

The PyCubed-Mini variant - designed for PocketQube and ultra-small satellites - presents additional challenges:

- Even tighter component spacing requiring advanced assembly techniques

- Miniaturized connectors that are fragile and difficult to work with

- Higher part costs per board due to premium on small-form-factor components

- More demanding thermal management in the reduced footprint

PROMETHEUS-1's successful use of PyCubed-Mini demonstrates the platform works, but the mission teams had access to university cleanrooms, professional assembly equipment, and experienced advisors. Most organizations lack these resources.

Commercial PyCubed: The Emergence of Professional Options

Recognizing these challenges, several organizations are now offering commercially manufactured PyCubed-based boards. This represents a major milestone for the platform and for accessible satellite development.

What Commercial PyCubed Offers

Quality Assurance: Professional manufacturers implement proper QA processes - incoming inspection, automated optical inspection (AOI), functional testing, burn-in, and environmental screening. You receive boards with documented test results and known-good performance.

Supply Chain Management: Commercial providers maintain component inventory, manage supplier relationships, and handle obsolescence issues. They absorb the risk of component availability rather than passing it to you.

Design Improvements: Commercial boards often incorporate lessons learned from the original design - improved thermal management, better RF performance, enhanced connector reliability, and component substitutions that improve availability without sacrificing functionality.

Technical Support: When you purchase commercial hardware, you get support. Questions are answered, integration issues are resolved, and firmware updates are provided. This support can be worth more than the hardware itself for teams racing toward launch deadlines.

Traceability: Commercial boards come with documentation suitable for mission assurance processes - serial numbers, test data, component traceability, and conformance certificates.

Blackwing Space: PyCubed-Derived Boards for Commercial Missions

Blackwing Space has developed a PyCubed-derived onboard computer specifically designed for commercial nanosatellite applications. Building on the proven PyCubed architecture, Blackwing's version addresses the key challenges that have limited broader adoption:

American Manufacturing: All Blackwing PyCubed boards are manufactured in the United States using domestic supply chains. This ensures ITAR compliance for U.S. government and defense customers who cannot use foreign-manufactured electronics.

Automotive-Grade Components: Leveraging Blackwing's core technology advantage, their PyCubed variant incorporates automotive-grade components from established North American suppliers. These parts offer better availability, longer product lifecycles, and known reliability data compared to standard commercial components.

Enhanced Testing: Every Blackwing board undergoes comprehensive functional testing, thermal cycling, and validation against mission profiles. Customers receive complete test documentation suitable for mission readiness reviews.

Production Scale: Unlike DIY builds or small-batch university fabrication, Blackwing manufactures boards in production quantities with consistent quality. Whether you need one board for a technology demonstrator or fifty for a constellation, you get the same proven hardware.

Integration Support: Blackwing provides engineering support for integrating PyCubed into complete satellite systems - power budgets, thermal analysis, mechanical interfaces, and software development. This turns the board from a component into a solution.

Pricing and Availability

While exact pricing varies based on configuration and quantity, commercial PyCubed-derived boards typically fall in the $1,200-2,500 range for single units, with volume discounts available for constellation deployments.

This represents a significant premium over the theoretical DIY cost, but remember that DIY cost doesn't include:

- Engineering time (worth $5,000-15,000 at typical aerospace rates)

- Risk of delays due to component shortages

- Risk of failed boards and rework

- Opportunity cost of focusing on hardware rather than mission-unique development

- Support and documentation

For most organizations, commercial boards deliver better value even at higher unit prices.

When DIY Still Makes Sense

Despite the advantages of commercial options, DIY PyCubed fabrication remains appropriate for certain situations:

Educational Objectives: If learning PCB design and assembly is part of your mission, building your own boards provides valuable hands-on experience.

Highly Customized Variants: Teams developing significant modifications to the baseline PyCubed design may need to fabricate custom boards anyway.

Research Programs: University research programs with existing fabrication capabilities and generous timelines can justify DIY approaches.

Budget-Constrained Projects: Teams with more time than money and access to university resources may still choose DIY fabrication.

However, even these use cases should carefully evaluate whether commercial boards might actually be more cost-effective when total project costs are considered.

The Future of PyCubed Availability

The transition from purely DIY to commercially available PyCubed boards marks an important evolution in satellite development. Several trends are emerging:

Standardization: As more providers offer PyCubed-compatible boards, interface standards and interoperability will improve. A mission developed on one vendor's board could be deployed on another's with minimal changes.

Ecosystem Growth: Commercial availability accelerates adoption, which drives development of complementary products - interface boards, sensor modules, communication systems - all designed to work seamlessly with PyCubed.

Mission Heritage: Each successful mission using commercial PyCubed boards adds to the platform's flight heritage, making it more attractive for risk-averse customers and enabling missions that require proven components.

Cost Reduction: As production volumes increase, commercial boards will become more affordable while maintaining quality and support advantages.

How to Purchase PyCubed for Your Mission

If you're ready to acquire PyCubed hardware for your satellite project, here's the practical path forward:

Step 1: Define Your Requirements

- Mission environment (orbit, duration, radiation exposure)

- Interface requirements (sensors, radios, payload connections)

- Power budget and generation capacity

- Form factor constraints (CubeSat size, mounting requirements)

- Timeline and budget

Step 2: Evaluate Options

- Commercial Boards: Contact providers like Blackwing Space for quotes, specifications, and lead times

- DIY Fabrication: Assess your internal capabilities, component availability, and true all-in costs

- Hybrid Approach: Purchase commercial boards for flight units while building DIY boards for development and testing

Step 3: Plan Integration

- Mechanical: Mounting, connector access, thermal paths

- Electrical: Power distribution, grounding, signal routing

- Software: Firmware customization, mission application development

- Testing: Functional verification, environmental qualification

Step 4: Engage Support Resources

- Commercial vendors provide integration engineering support

- The PyCubed community offers forums and documentation

- University collaborators can provide expertise and facilities

Making the Buy vs. Build Decision

The choice between purchasing commercial PyCubed boards and building your own ultimately depends on your specific situation. Here's a decision framework:

Choose Commercial If:

- Your timeline is constrained (less than 12 months to integration)

- You lack in-house PCB assembly and testing capabilities

- You need documented quality assurance for mission approval

- You want to minimize technical risk

- You're building multiple satellites or a constellation

- Your engineering resources are better spent on mission-unique development

- You require ITAR-compliant U.S. manufacturing

Choose DIY If:

- Educational experience is a primary mission objective

- You have expert assembly capabilities and test equipment

- Your timeline is flexible (18+ months)

- You're making significant design modifications anyway

- Budget is extremely constrained but time is abundant

- You have established component supply relationships

Beyond the Board: Complete Mission Solutions

Increasingly, satellite developers are looking beyond individual components to complete mission solutions. Providers like Blackwing Space are responding by offering:

- Complete satellite buses with integrated PyCubed-based avionics

- Turnkey mission packages including launch integration and ground systems

- Mission design and analysis services

- Operations support and training

This shift from "purchasing a board" to "purchasing a mission solution" reflects the maturation of the small satellite industry. Organizations increasingly recognize that their core value isn't in fabricating circuit boards - it's in the unique payload, application, or service their satellite enables.

Conclusion: The Democratization of Satellite Computing

PyCubed represents exactly the kind of innovation the space industry needs: capable, accessible, and built on open foundations. The emergence of commercial PyCubed-derived boards takes this democratization to the next level.

Organizations can now access proven satellite computing platforms without requiring specialized electronics manufacturing capabilities. University teams can focus on their science payloads rather than debugging circuit boards. Commercial ventures can accelerate development using battle-tested foundations.

The question is no longer "where can I buy PyCubed?"- it's "which PyCubed solution best fits my mission?"

Whether you choose to build your own boards or purchase commercial variants from providers like Blackwing Space, PyCubed offers a proven path to orbit. The platform's open architecture means you're never locked in, while commercial availability means you're never stuck without options.

As more missions fly, more boards get produced, and more organizations contribute to the ecosystem, PyCubed will only become more capable and more accessible. That's good news for anyone trying to get a satellite to orbit, and excellent news for the future of space development.

Ready to discuss PyCubed options for your mission? Contact Blackwing Space to learn more about commercially manufactured, U.S.-made, PyCubed-derived flight computers designed for the demands of modern nanosatellite missions.